What is Probe Control?

A question that we often get is...

"Why is the temperature of my pan different than the temperature of my food?"

Simply put, the temperature of your cooking vessel is not always the same temperature as what is inside of it. If you have a small volume of liquid such as a one quart saucepan, their temperatures may quickly align. If you place a five gallon stock pot on the same burner, it will take far longer to heat that volume. It is also much harder to maintain a given temperature. The temperature of the contents and the vessel itself (after a very long time) may get close to equilibrium, but may not even reach it because of ambient factors or evaporative cooling on the surface of the fluid. Let's switch gears and use a familiar analogy..

Consider heating / air conditioning. If you set your house to 72ºF and the heat or cooling system turns on, it will blow very hot or very cold air to get you to your set point (72ºF) quickly. The air coming out of the vents is not 72ºF. If it were, it would take a very long time to reach equilibrium, if at all.

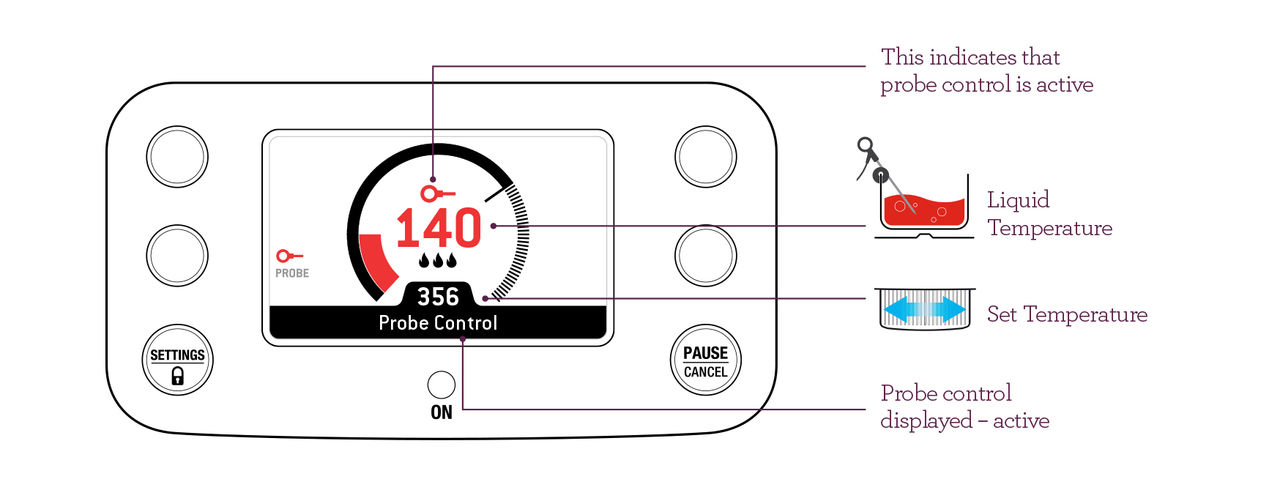

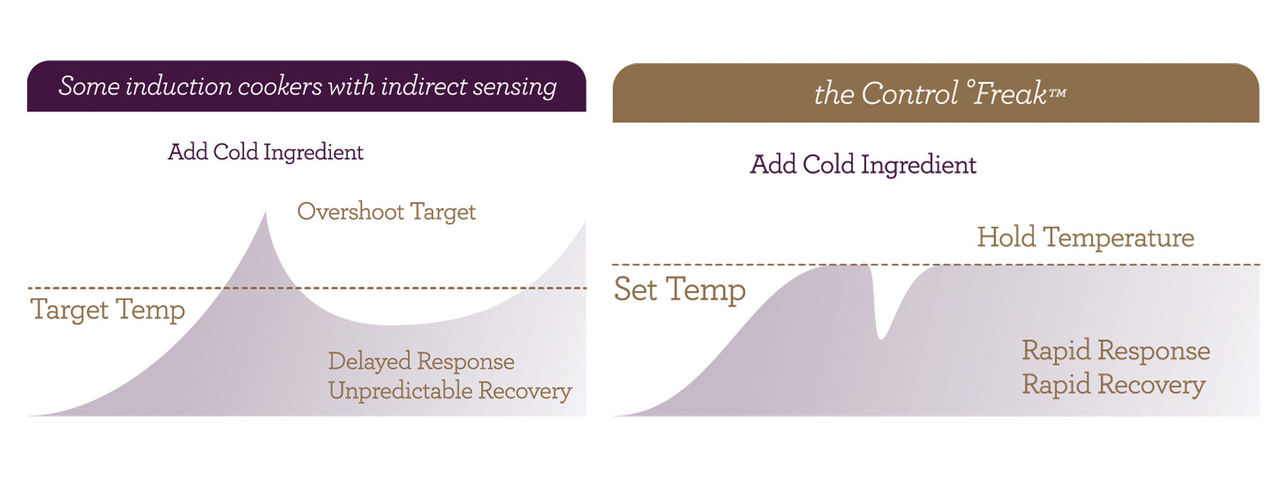

The same rules apply here. Because of the unique PID programming of the Control ºFreak, this is where we would deploy Probe Control™. This is because Probe Control™ automatically monitors and adjusts the temperature of your pan / pot in order to maintain your desired temperature. Most induction units have a simple on/off control and which is why you need to constantly adjust them when you add or remove food. This saves time and keeps the cooking process in control.

What is PID control?

PID stands for Proportional Integral Derivative. Sound confusing? Maybe, but let's use another familiar analogy. Consider the cruise control setting in your car.

• Imagine that you are driving 30mph along a flat road. You press and release the pedal to maintain 30mph. This is proportional control.

• But what if you begin heading up a hill? Your speed will begin to drop. The faster the speed drops, the more acceleration you need to apply. This is derivative control.

• If you have a small difference between your target speed and actual speed, such as the slight variations in your foot pressure, the proportional control is too small to be effective. If this small difference remains uncorrected, this error will get larger and larger. This is fixed by integral control. This helps your car reach the correct speed and stay there.

How does this help me?

Cooking is a complex science. The physics of cooking are complex enough to make even the most seasoned chef blush. When a filet is placed in a hot sauté pan or cold food is dropped into a fryer of hot oil, there is a transfer of heat energy. It takes mindfulness of the cook to be aware of this change in temperature, adjust, monitor and readjust to achieve a perfect result.

When the order tickets begin streaming in, the headspace of a cook begins to fill. It's quite likely in this situation that the ability to adjust, monitor, and readjust the temperatures of every cooking item becomes less and less. The Control ºFreak uses PID programming to do all of this automatically. It's able to control both wet and dry cooking methods within 1.8 degrees.